ARCHIDEX 2025, held from July 23-26 , is one of Southeast Asia’s highly influential comprehensive building materials exhibitions. The total area of this exhibition exceeds 26000 square meters, and it is expected to attract 700+international exhibitors and 40000+professional visitors, setting a record for the largest scale of construction exhibitions in Malaysia.

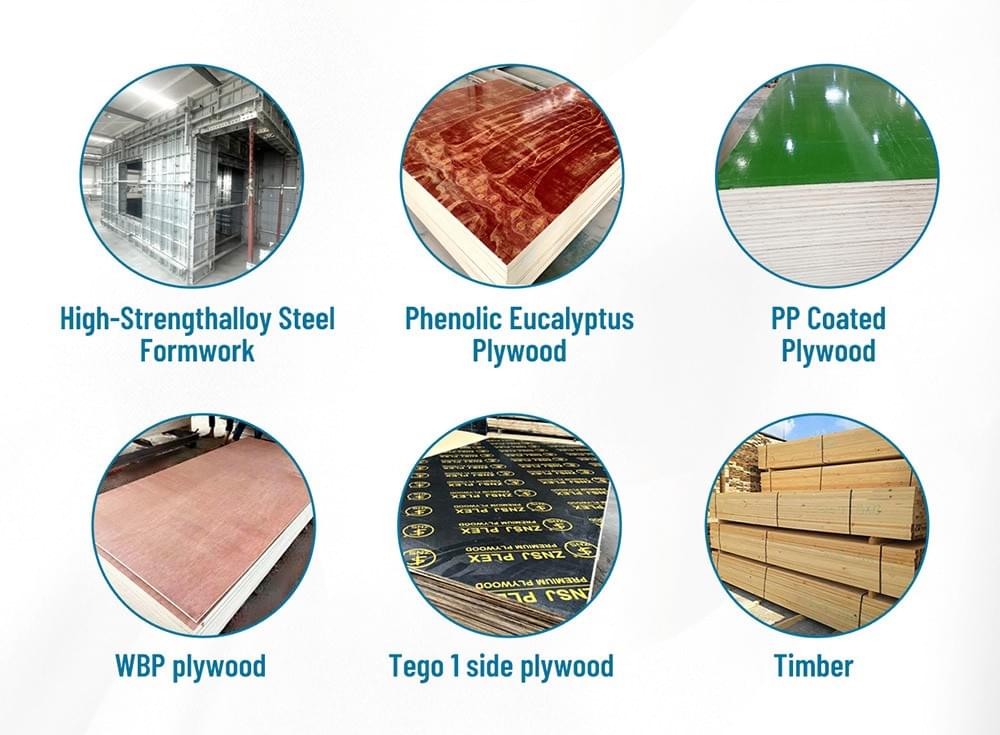

Zhongnan Shenjian Group is committed to becoming the most competitive integrated service provider in the global construction formwork industry. As one of ZNSJ’s most strategic markets, Southeast Asia served as the ideal stage to showcase a wide range of high-performance, economical building formwork products—including the High-strength alloy steel formwork, phenolic eucalyptus plywood, PP coated plywood, WBP plywood, Tego 1 side plywood and timber.

The preferred choice for high-rise buildings - ZNSJ High-strength alloy steel formwork

The panel and frame are bent and formed in one step, resulting in a flat surface and high production efficiency. Reinforcements are welded using automatic laser welding, ensuring no deformation or cracking. The flatness error of the board surface is ≤ 0.3mm, and the first acceptance rate of the verticality of high-rise buildings is 99.2%.

Our steel formwork weighs only 25kg/㎡, allowing for easy handling and installation by two people. It can effectively solve the current situation of high labor costs and rental of lifting equipment in overseas local areas.

Designed to improve ROI for contractors, these technologies demonstrate ZNSJ’s commitment to both durability and creativity.

The star product widely used in the industry - ZNSJ Construction Plywood

Construction Plywood is lightweight and can be manually transported and installed without the need for large mechanical assistance. Our plywood formwork also supports on-site manual cutting, adapting to complex construction shapes and increasing installation efficiency by 40%. It can make the concrete surface smoother and more beautiful for decoration, reducing the plastering process. It is easy to de-molding, and will greatly reduce the total time of the concrete forming by 30%, helping to deliver projects on schedule during the rainy season in Malaysia.

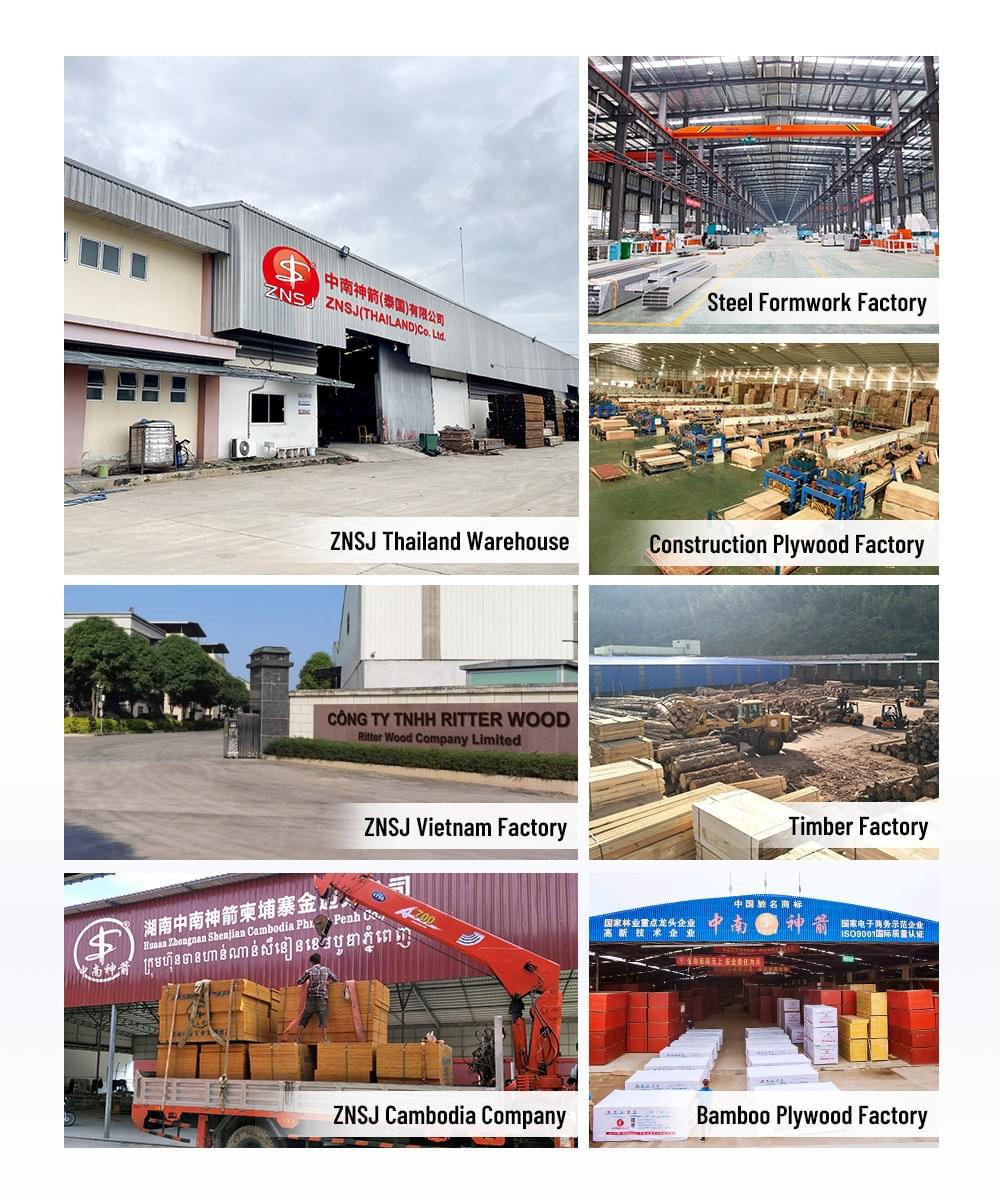

After more than 20 years of development, ZNSJ group has 3 major R&D and production bases and 18 subsidiaries and the headquarter is in Changsha, China. Our commitment to excellence has led us to establish the Riiter Wood Plywood Factory in Hanoi, Vietnam and two direct-operated overseas warehouses in Thailand. Thailand's direct warehouse can reach the construction site within 48 hours, increasing the response speed of emergency orders by three times; The construction formwork has passed the EU CE certification, with a formaldehyde emission of ≤ 0.3mg/L, in compliance with Malaysia's green building standards. The products are exported to more than 60 countries and regions in Southeast Asia, the Middle East, Africa, South America, Europe and the United States.

From high-strength alloy steel formwork to traditional plywood, ZNSJ’s full-spectrum products at ARCHIDEX 2025 demonstrate the company’s commitment to innovation, reliability, and user value. As ZNSJ continues expanding its global footprint, it remains steadfast in its mission: to to becoming the most competitive integrated service provider in the global construction formwork industry.