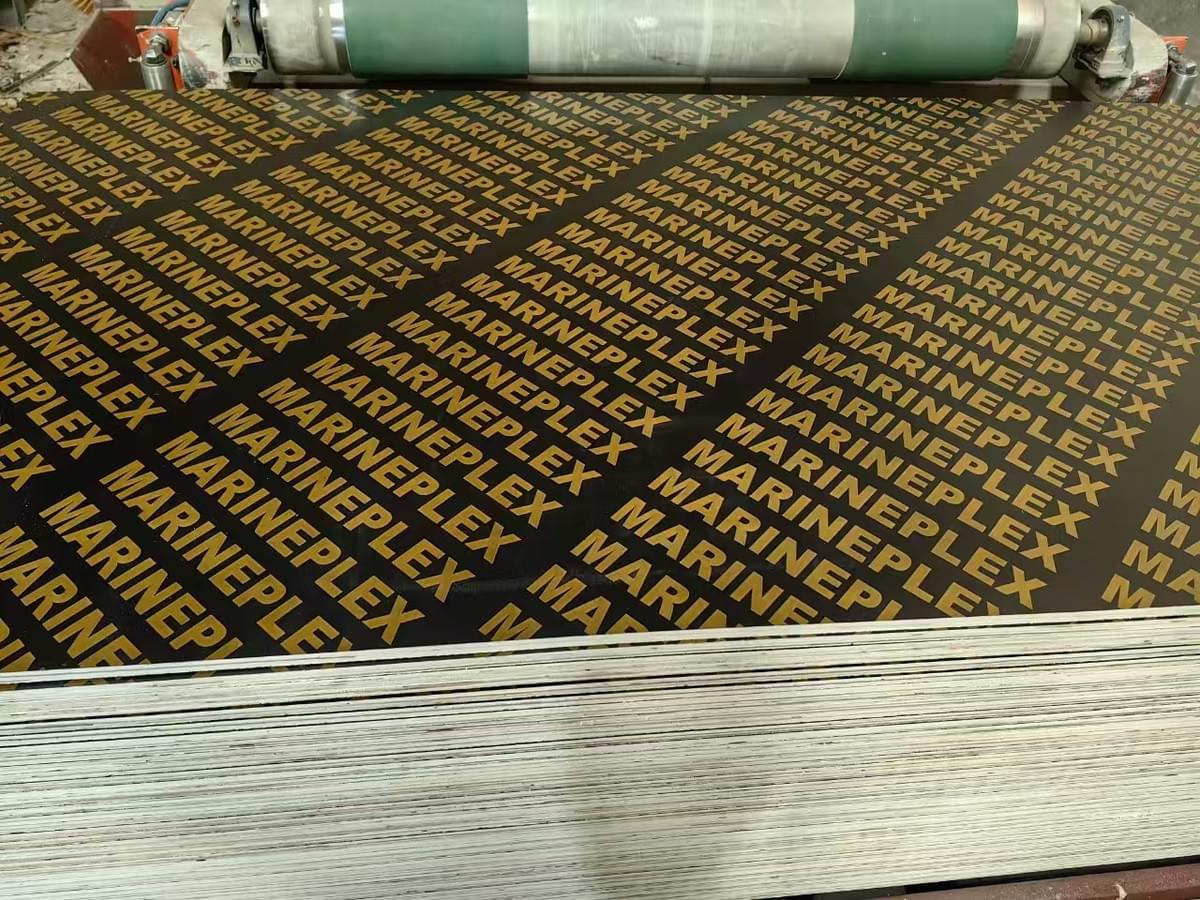

Recently, we successfully completed the container loading and shipment of 2,080 sheets of 1220×2440×18mm poplar core film faced plywood bound for Dammam Port, Saudi Arabia. The client had strict requirements for the delivery timeline, and to align with their construction schedule, we coordinated production, logistics, and container allocation efficiently. This ensured on-time shipment and strengthened the client’s trust. Poplar core film faced plywood, known for its lightweight yet high strength and easy application, has become a mainstream choice for residential, commercial, and industrial projects in the Saudi market.

Unlike standard plywood sales, this collaboration involved a tailored approach based on the client’s project location and material needs. Leveraging our experience with previous projects, we analyzed local demands for heat resistance, surface flatness, and reuse cycles in Saudi Arabia. We then recommended a more cost-effective configuration of poplar core film faced plywood to help the client maintain construction quality while optimizing their budget.

This successful transaction was not only due to the product’s performance but also our team’s deep understanding of the Saudi construction materials market. During the negotiation process, we provided detailed market insights and competitive product comparisons, boosting the client’s confidence in their procurement decisions. With its excellent demolding performance and high reuse rate, our poplar core film faced plywood has once again earned the client’s recognition, laying a solid foundation for ongoing repeat cooperation.