High quality LVL Scaffold Planks for construction

Good toughness and high strength, this product has three times the strength of solid wood products of the same size, suitable for load-bearing use.

Product use: Building structural wooden beams, scaffold pedals, and other scaffold components.

Product name | High quality LVL Scaffold Planks for construction |

Materials | Pine, Radiata Pine |

Size | Thickness: 38mm,42mm etc. Width: 225mm, 230mm, 235mm etc. Length: 2m,3.9m, 4m, 6m etc. |

Painting | Green, Yellow or customize |

Tolerance | T&W: ±1mm; L: ±2 |

Formaldehyde emission | E2, E1 etc. |

Glue | Melamine glue, WBP glue, Phenolic glue etc. |

Application | Scaffolding Planks, contruction etc. |

Moisture Content | below 15% |

Leading time | 15 - 30 Days |

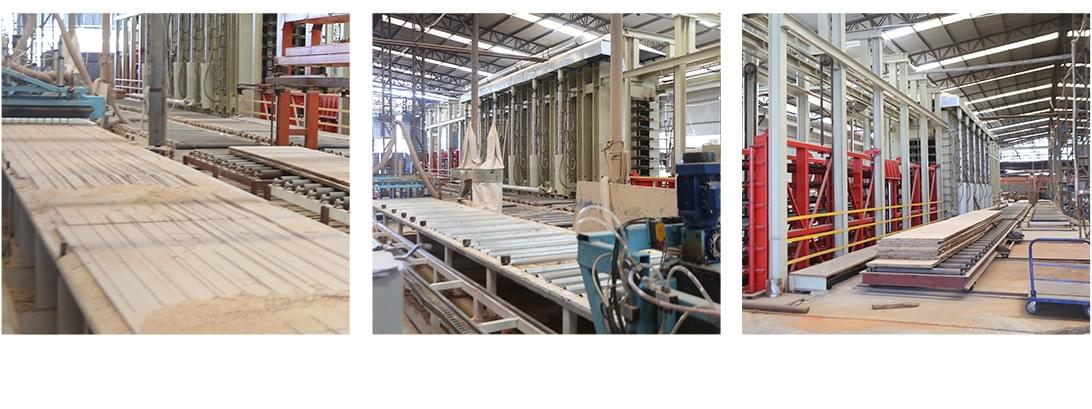

LVL PRODUCTION PROCESS:

STEP1: Cut the log to size.

STEP 2: Peeling the Log to the veneer.

STEP 3: Drying the Veneer.

STEP 4: Grading the Veneer. A, B, C.

STEP 5: Gluing the veneer.

STEP 6: Laying the veneer.

STEP 7: Hot pressure.

STEP 8: Sanding the core.

STEP 9: Cutting to size.

STEP 10: Packaging.

LVL product has many advantages over sawn milled lumber:

- LVL can control the specification: LVL can be produced in almost Thickness, Width, Length, Moisture Content, Uniform. The length of the LVL is not dependent on the log size, due to the manufacturing technique

- It can be used for pallet. Due to the hot pressing and formaldehyde, it don't need fumigation

- LVL is a high strength and can be used for scaffold board, but very lighter than sawn timber. Lower price.

- Using wood resources efficiently.

2) Outer packing: Pallets are covered with 2mm package plywood or carton and then steel tapes for strengthening.