In construction, the choice of film faced plywood can make a big difference in both performance and cost. One-time pressing film faced plywood is manufactured through a single hot-pressing process. It is budget-friendly and suitable for short-term or low-turnover projects where affordability is the main concern.

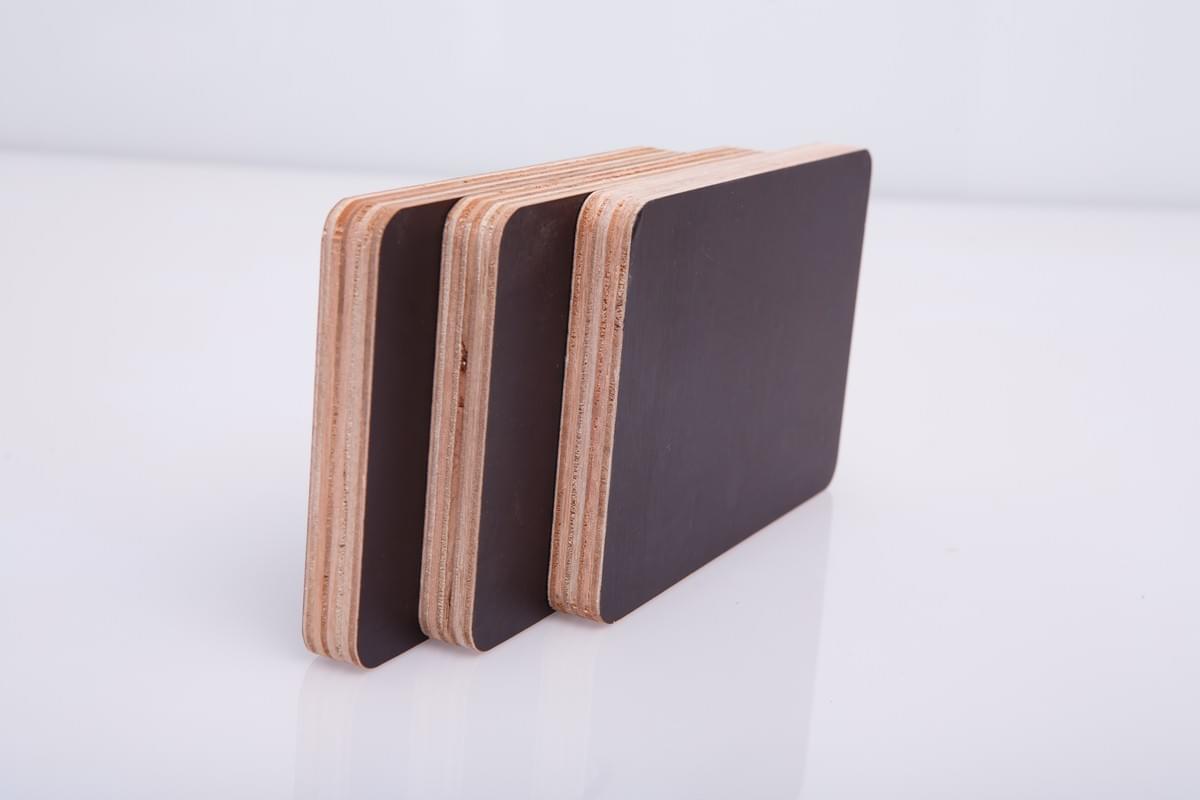

For projects that require higher durability and better surface quality, two-time pressing film faced plywood is the preferred choice. After the first hot pressing, each sheet is sanded, glue-filled, and hot-pressed again with a high-quality protective film. This double pressing creates a smoother surface, tighter edges, and superior resistance to water, abrasion, and repeated use—making it ideal for high-rise buildings, bridges, and other demanding construction projects.

When comparing the two, the decision is not only about initial price but also long-term cost efficiency. One-time pressing film faced plywood is perfect for quick builds, while two-time pressing film faced plywood offers extended lifespan and higher reuse rates, saving money over multiple construction cycles. Choosing the right film faced plywood ensures better performance, longer service life, and greater project value.